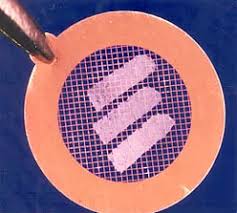

TEM grids with support film

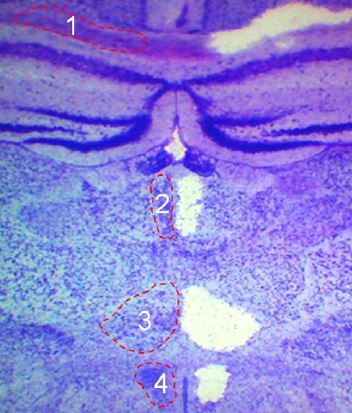

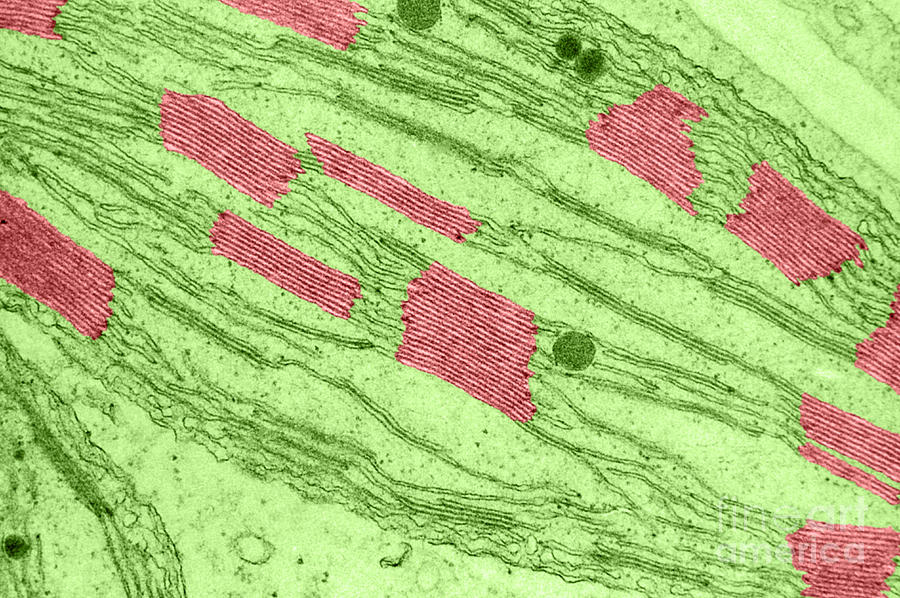

The EM Resolutions team have many years experience working in the Microscopy industry. We have been making high quality support films and calibration standards for over 20 years and now supply these and other consumables for Electron Microscopy direct to customers all over the world. EMR TEM support films are produced with the requirement of the electron microscopist in mind. The clean production techniques yield reliable, consistent quality TEM support films without contamination issues. Stringent quality control procedures include checking with a TEM.

Formvar film on grids

Formvar only F range support films are an excellent solution when viewing fragile sections in the TEM. They are particularly good for supporting ultrathin cryosections

Formvar film on Copper 100 mesh (50) F100Cu

Formvar film on Copper 200 mesh (25) F200Cu25

Formvar film on Copper 200 mesh (50) F200Cu

Formvar film on Copper 200 mesh (100) F200Cu100

Formvar film on Copper 300 mesh (25) F300Cu25

Formvar film on Copper 300 mesh (50) F300Cu

Formvar film on Copper 300 mesh (100) F300Cu100

Formvar film on Copper 400 mesh (25) F400Cu25

Formvar film on Copper 400 mesh (100) F400Cu100

Formvar film on Copper 400 mesh (50) F400Cu

Carbon film on grids

Carbon support films provide a continuous thin electron transparent support for viewing nano and virus like particles. They also provide increased stability of specimens when imaging at very high magnifications. A good solution for imaging nanoparticles. Carbon film thickness is in the range of 15-20nm providing a thin consistent carbon film. If your application requires a slightly thicker or thinner film then please tell us and we can modify future orders to your requirements.

Carbon film on Copper 200 mesh (25) C200Cu25

Carbon film on Copper 200 mesh (50) C200Cu

Carbon film on Copper 200 mesh (100) C200Cu100

Carbon film on Copper 300 mesh (25) C300Cu25

Carbon film on Copper 300 mesh (50) C300Cu

Carbon film on Copper 300 mesh (100) C300Cu100

Carbon film on Copper 400 mesh (25) C400Cu25

Carbon film on Copper 400 mesh (50) C400Cu

Carbon film on Copper 400 mesh (100)C400Cu100

Formvar Carbon film on grids

Formvar Carbon support films (FC range) offer a good solution where a carbon only film is too fragile to withstand pre-treatments or additional processing. They also provide the option to remove the formvar before use if preferred.

Formvar Carbon Film on Copper 100 mesh (25) FC100Cu25

Formvar Carbon Film on Copper 100 mesh (50) FC100Cu

Formvar/Carbon film on Copper 200 mesh (25) FC200Cu25

Formvar/Carbon film on Copper 200 mesh (50) FC200Cu

Formvar/Carbon film on Copper 200 mesh (100) FC200Cu100

Formvar/Carbon film on Copper 300 mesh (25) FC300Cu25

Formvar/Carbon film on Copper 300 mesh (50) FC300Cu

Formvar/Carbon film on Copper 300 mesh (100) FC300Cu100

Formvar/Carbon film on Copper 400 mesh (25) FC400Cu25

Formvar/Carbon film on Copper 400 mesh (50) FC400Cu

Formvar/Carbon film on Copper 400 mesh (100) FC400Cu100

Formvar/Carbon film on Nickel 200 mesh (25) FC200Ni25

Formvar/Carbon film on Nickel 200 mesh (50) FC200Ni

Formvar/Carbon film on Nickel 200 mesh (100) FC200Ni100

Formvar/Carbon film on Nickel 300 mesh (25) FC300Ni25

Formvar/Carbon film on Nickel 300 mesh (50) FC300Ni

Formvar/Carbon film on Nickel 300 mesh (100) FC300Ni100

Formvar/Carbon film on Nickel 400 mesh (25) FC400Ni25

Formvar/Carbon film on Nickel 400 mesh (50) FC400Ni

Formvar/Carbon film on Nickel 400 mesh (100) FC400Ni100

Formvar/Carbon film on Gold 200 mesh (25) FC200Au25

Formvar/Carbon film on Gold 200 mesh (50) FC200Au

Formvar/Carbon film on Gold 300 mesh (25) FC300Au25

Formvar/Carbon film on Gold 300 mesh (50) FC300Au

Formvar/Carbon film on Gold 400 mesh (25) FC400Au25

Formvar/Carbon film on Gold 400 mesh (50) FC400Au

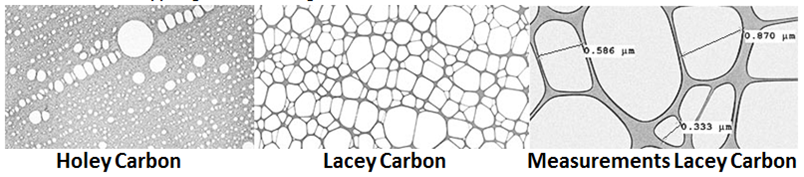

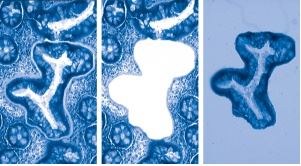

Holey, Lacey film on grids

Lacey Carbon support films provide a wide range of hole sizes and offer a cost effective solution where are a continuous film is not desirable. Lacey Carbon supports are stronger than Holey carbon supports and ideal for specimens requiring more rigorous pre-treatments. Our experience of developing methods over 30 years enables us to have greater control over the formation of the holes. If your application requires a particular hole size or you would prefer slightly thicker or thinner film then please tell us and we can modify future orders to your requirements. Also included in our range is a Lacey Formvar Carbon support film that retains a Lacey Formvar backing for additional strength.

Lacey Carbon film on Copper 200 mesh (25) LC200Cu25

Lacey Carbon film on Copper 200 mesh (50) LC200Cu

Lacey Carbon film on Copper 200 mesh (100) LC200Cu100

Lacey Carbon film on Copper 300 mesh (25) LC300Cu25

Lacey Carbon film on Copper 300 mesh (50) LC300Cu

Lacey Carbon film on Copper 300 mesh (100) LC300Cu100

Lacey Carbon film on Copper 400 mesh (25) LC400Cu25

Lacey Carbon film on Copper 400 mesh (50) LC400Cu

Lacey Carbon film on Copper 400 mesh (100) LC400Cu100

Lacey Carbon film on Nickel 200 mesh (25) LC200Ni25

Lacey Carbon film on Nickel 200 mesh (50) LC200Ni

Lacey Carbon film on Nickel 200 mesh (100) LC200Ni100

Lacey Carbon film on Nickel 300 mesh (25) LC300Ni25

Lacey Carbon film on Nickel 300 mesh (50) LC300Ni

Lacey Carbon film on Nickel 300 mesh (100) LC300Ni100

Lacey Carbon film on Nickel 400 mesh (25) LC400Ni25

Lacey Carbon film on Nickel 400 mesh (50) LC400Ni

Lacey Carbon film on Nickel 400 mesh (100) LC400Ni100

Lacey Carbon film on Gold 200 mesh (25) LC200Au25

Lacey Carbon film on Gold 200 mesh (50) LC200Au

Lacey Carbon film on Gold 300 mesh (25) LC300Au25

Lacey Carbon film on Gold 300 mesh (50) LC300Au

Lacey Carbon film on Gold 400 mesh (25) LC400Au25

Lacey Carbon film on Gold 400 mesh (50) LC400Au

Lacey Carbon film on H7 Copper (25) LCH7Cu25

Lacey Carbon film on H7 Copper (50) LCH7Cu

Lacey Carbon film on H7 Copper (100) LCH7400Cu100

Lacey Formvar Carbon film on Copper 300 mesh (25) LFC300Cu25

Lacey Formvar Carbon film on Copper 300 mesh (50) LFC300Cu

Holey Carbon support films (HC range) provide a carbon support film with a range of relatively small hole sizes, particularly suited for suspensions of nano and virus like particles. They offer a cost effective solution where are a continuous film is not desirable. If you need a particular hole size or would prefer slightly thicker or thinner films then please tell us and we can modify future orders to your requirements.

Holey Carbon film on Copper 200 mesh (25) HC200Cu25

Holey Carbon film on Copper 200 mesh (50) HC200Cu

Holey Carbon film on Copper 200 mesh (100) HC200Cu100

Holey Carbon film on Copper 300 mesh (25) HC300Cu25

Holey Carbon film on Copper 300 mesh (50) HC300Cu

Holey Carbon film on Copper 300 mesh (100) HC300Cu100

Holey Carbon film on Copper 400 mesh (25) HC400Cu25

Holey Carbon film on Copper 400 mesh (50) HC400Cu

Holey Carbon film on Copper 400 mesh (100) HC400Cu100

Holey Carbon film on Nickel 200 mesh (25) HC200Ni25

Holey Carbon film on Nickel 200 mesh (50) HC200Ni

Holey Carbon film on Nickel 200 mesh (100) HC200Ni100

Holey Carbon film on Nickel 300 mesh (25) HC300Ni25

Holey Carbon film on Nickel 300 mesh (50) HC300Ni

Holey Carbon film on Nickel 300 mesh (100) HC300Ni100

Holey Carbon film on Nickel 400 mesh (25) HC400Ni25

Holey Carbon film on Nickel 400 mesh (50) HC400Ni

Holey Carbon film on Nickel 400 mesh (100) HC400Ni100

Holey Carbon film on Gold 200 mesh (25) HC200Au25

Holey Carbon film on Gold 200 mesh (50) HC200Au

Holey Carbon film on Gold 300 mesh (25) HC300Au25

Holey Carbon film on Gold 300 mesh (50) HC300Au

Holey Carbon film on Gold 400 mesh (25) HC400Au25

Holey Carbon film on Gold 400 mesh (50) HC400Au

Holey Carbon film on H7 Copper (25) HCH7Cu25

Holey Carbon film on Copper H7 (50) HCH7Cu

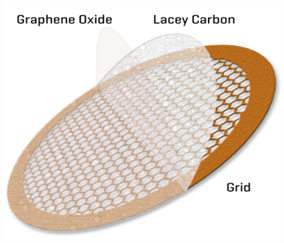

Graphene film on grids

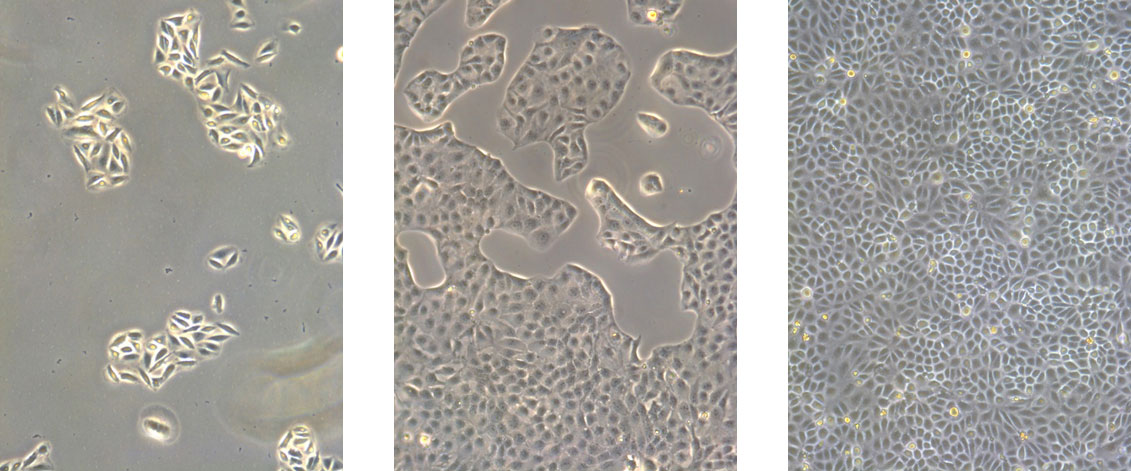

Graphene Oxide are super thin (<1nm) naturally hydrophilic support films. Pre-treatment of GO support films is not necessary before using. The hydrophilic surface will facilitate the even spread of particle suspensions across the grid. We would actively discourage any form of plasma cleaning or glow discharge as it will damage the support film.

Graphene and Graphene Oxide (GO) have been known for some time to offer distinct benefits as thin support films for TEM. Whilst Graphene grown by CVD offers the possibility of a continuous film the methods of production are technically complex and expensive for large scale manufacture of coated TEM grids. Graphene oxide offers a cost effective alternative to Graphene. GO monolayers are typically 50% thinner than the equivalent carbon support film offering an ideal solution for viewing nanoparticles by TEM where a continuous support is necessary. Graphene oxide films are almost transparent under the electron beam and not easily visible under an optical microscope. As part of our quality process we check each batch using TEM imaging and diffraction to characterise the grids.

EM Resolutions can offer coated grids with a varying thicknesses of GO to best suit your application. When deciding which is best for you one needs to consider a compromise between grid coverage vs the number of layers (thickness of GO).

We ensure that the GO covers a given % of holes in the support film using three key metrics:

(1) % of the area of the grid holes covered (coverage)

(2) the average number of GO layers across each hole

(3) what % of the covered holes are monolayer.

For good ‘monolayer’ coverage we would expect ~ 50% coverage, of which the majority is monolayer (i.e. a total of ~ 30% monolayer across the grid area). Depending on your application you need to decide if it is more important to have high coverage or a high monolayer fraction.

For good overall coverage of> 80% coverage we would expect typically 2-3 layers of GO with < 20% as monolayer GO. These films are ideal for carbonaceous particles where carbon supports cannot be used.

EM Resolutions offers GO support films on a range of carefully selected coated grid types. We use holey and lacey support films on hexagonal grids to ensure the most even coverage of GO that is suitable for your application.

Graphene oxide on hexagonal Holey Copper 300 mesh (10) GOHC300HxCu10

Graphene oxide on hexagonal Holey Copper 300 mesh (25) GOHC300HxCu25

Graphene oxide on hexagonal Holey Copper 300 mesh (50) GOHC300HxCu50

Graphene oxide on hexagonal Lacey Copper 300 mesh (10) GOLC300HxCu10

Graphene oxide on hexagonal Lacey Copper 300 mesh (25) GOLC300HxCu25

Graphene oxide on hexagonal Lacey Copper 300 mesh (50) GOLC300HxCu50

Silicon Nitrite Membrane

Silicon Nitride membranes (TEM windows) have the advantage of being chemically inert and mechanically robust, being able to withstand temperatures >1000°C. They are particularly suitable for conducting nanotechnology experiments directly on their surface over a wide temperature range. Silicon Nitride grids are compatible with correlative negative staining electron microscopy and tip-enhanced Raman spectroscopy for use in the detection of micro-organisms.

NANOPOROUS Silicon Nitride 20 nm thick TEM Windows (Single 500 micron window) NANOPOROUS One Window (1) 500×500µm SN100-P20Q05

Silicon Nitride Lift-Out TEM Windows with Gold Contacts One Window with free edge (1) 100×500µm; 200nm Au Contacts SN100-LFT-AU

Silicon Nitride Lift-Out TEM Windows One Window with free edge(1) 100×500µm SN100-LFT

Silicon Nitride 50 nm thick TEM Windows (9 windows) Nine Windows: (9) 100×100µm SN100-A50Q33

Silicon Nitride 50 nm thick TEM Windows (Single 1000 micron window) One Window: (1) 1000×1000µm SN100-A50Q10

Silicon Nitride 50 nm thick TEM Windows (Single 500 micron window) One Window: (1) 500×500µm SN100-A50Q05

Silicon Nitride 50 nm thick TEM Windows (Single 100 micron window) One Window: (1) 100×100µm SN100-A50Q01

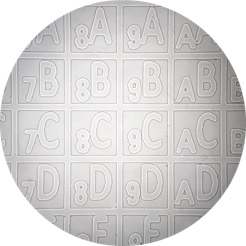

MICROPOROUS Silicon Nitride 50 nm thick TEM Windows (Single 500 micron window) MICROPOROUS (2.0 µm pores with labeled grid) / One Window: (1) 500×500µm SN100-A50MP2Q05

Silicon Nitride 20 nm thick TEM Windows (9 windows) Nine Windows: (8) 100×100µm, (1) 100×350µm SN100-A20Q33

Silicon Nitride 20 nm thick TEM Windows (Single 500 micron window) One Window: (1) 500×500µm SN100-A20Q05

MICROPOROUS Silicon Nitride 20 nm thick TEM Windows (Single 500 micron window) MICROPOROUS (2.0 µm pores with labeled grid) /One Window: (1) 500×500µm SN100-A20MP2Q05

Silicon Nitride 10 nm thick TEM Windows (9 LARGE windows) Nine Large Windows (8) 250×250µm, (1) 250×500µm SN100-A10Q33B

Silicon Nitride 10 nm thick TEM Windows (9 windows) Nine Windows: (8) 100×100µm, (1) 100×350µm SN100-A10Q33

Silicon Nitride 5 nm thick TEM Windows (2 slots – CONDUCTIVE) Two Windows: (2) 50×1500µm CONDUCTIVE SN100-A05QL-C

Silicon Nitride 5 nm thick TEM Windows (9 SMALL windows) Nine Windows (SMALL): (8) 50×50, (1) 50×100µm SN100-A05Q33A

Silicon Nitride 5 nm thick TEM Windows (Single 25 micron window) One Window: (1) 25×25µm SN100-A05Q00

TEM Window Handling Tweezer K6 (Plastic) K6TWZR

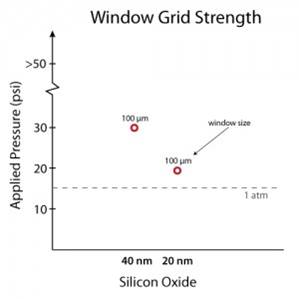

Silicon Dioxide Membrane

Every batch of TEM windows is tested for robustness and inspected under the TEM. Prior to packaging, each TEM window is individually inspected in an optical microscope.

Silicon Dioxide G-FLAT TEM Windows (Single 1000 micron window) One Window: 1000×1000µm SO100-GFLAT75

Silicon Dioxide 40 nm thick TEM Windows (9 windows) Nine Windows: (9) 100×100µm SO100-A40Q33

Silicon Dioxide 20 nm thick TEM Windows (9 windows) Nine Windows: (9) 100×100µm SO100-A20Q33

TEM Window Handling Tweezer K6 (Plastic) K6TWZR

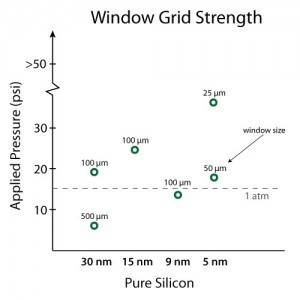

Pure Silicon Membrane

Every batch of TEM windows is tested for robustness and inspected under the TEM. Prior to packaging, each TEM window is individually inspected in an optical microscope.

NANOPOROUS Pure Silicon TEM Windows (9 windows) NANOPOROUS, Nine Windows: (8) 100×100, (1) 100×350µm US100-P30Q33

NANOPOROUS Pure Silicon TEM Windows (Single 500 micron window) NANOPOROUS, One Window: (1) 500×500µm US100-P30Q05

Single Crystal Silicon 35 nm thick TEM Windows (9 windows)<100>Single Crystal Silicon; Nine Windows: (8) 100×100µm, (1) 100×350µm US100-C35Q33

Non-Porous Pure Silicon 15 nm thick TEM Windows (9 windows) Nine Windows: (8) 100×100µm, (1) 100×350µm US100-A15Q33

Non-Porous Pure Silicon 15 nm thick TEM Windows (2 slots) Two Windows: (2) 100×1500µm US100-A15L

Non-Porous Pure Silicon 9 nm thick TEM Windows (9 windows) Nine Windows: (8) 100×100µm, (1) 100×350µm US100-A09Q33

Non-Porous Pure Silicon 9 nm thick TEM Windows (2 slots) Two Windows: (2) 100×1500µm US100-A09L

Non-Porous Pure Silicon 5 nm thick TEM Windows (9 SMALL windows) Nine Windows (SMALL): (8) 50×50, (1) 50×100µm US100-A05Q33A

Non-Porous Pure Silicon 5 nm thick TEM Windows (single 25 micron window) One Window: (1) 25×25µm US100-A05Q00

Non-Porous Pure Silicon 5 nm thick TEM Windows (2 slots) Two Windows: (2) 50×1500µm US100-A05L

TEM Window Handling Tweezer K6 (Plastic) K6TWZR

关闭返回

关闭返回